CONDUCTIVE INKS

Functional Pad Printing Inks

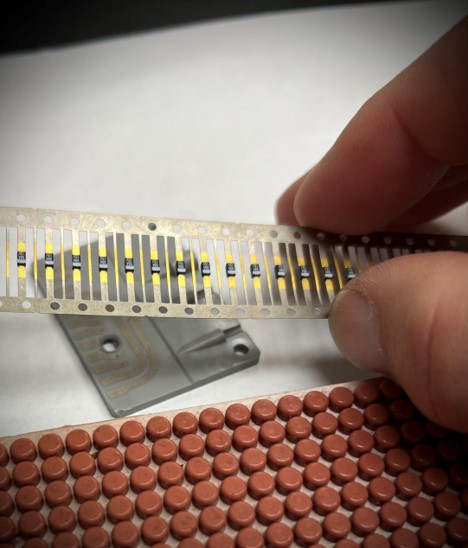

When most people think about padprinting they think about decorative printing or marking on things such as golfballs, knobs, bezels, medical devices, appliance panels and so forth. However, with the right equipment and expertise it is possible to pad print functional materials in ways you may have never considered.

At Innovative, we have decades of experience in functional pad printing inks and we have the equipment to make it work. Our 100% electric pad printing equipment allows for precise control of all parts of the print cycle and makes printing difficult materials possible.

Instead of screen printing or dispensing, have you considered pad printing your conductive or dielectric material? Pad printing allows precise amounts of conductive inks to be printed on parts where it is impossible to screen print or dispense. Is there a feature in your molded part that would interfere with screen printing? Is it irregularly shaped or contoured? Pad printing your conductive ink may be the solution. Typical cycle times are faster because of the nature of pad printing and the amount of ink necessary for start up is typically lower. In addition, the quality of the image in terms of line width and detail can be controlled in a way that is impossible with dispensing or screen printing.

We also have extensive experience in pad printing adhesives, and lubricants. Do you need to get your adhesive precisely located around a feature, but not on the feature, or inside the feature? Is a thin film of lubricant called for, but other forms of application result in excess? Pad printing could likely be a solution.

Do you have a proprietary chemistry that you need to put onto a test kit, a medical patch, a contact lens? We can work with you to make your compound pad printable and put it precisely where you need it.

Materials:

- Conductive Pad Printing Inks

- Dielectric Pad Printing Inks

- Radio Opaque Pad Printing Inks

- Pad Printable Adhesives

- Pad Printable Lubricants

- Specialty Chemistry

Applications:

- Medical Electrode Inks

- Solder Masking

- Membrane Switches

- Solar Cells

- Flexible Conductive Circuits

- Radio Opaque for Catheters, Balloons, etc

- EMI / RFI Shielding

- Precise Lubrication i Precision Assemblies

- Fine Detail/ Precision Control Adhesive Application

Let’s talk about your application. Pad printing may not only be feasible, it may be the best solution for your product.