TOSH: The Advantage is Built In

If you’ve taken the time to open this file and read it, I would like to thank you personally. My name is Trent Pepicelli and I’ve been the guy in charge telling the USA about TOSH for more than a decade. If you were expecting a dry document of facts and figures alone, I apologize. There is plenty of technical info below, but at the heart of it, this document was born from my passion about pad printing and the TOSH equipment that it has been my life’s work to sell, service and support.

Since the first time I put my hands on a piece of TOSH equipment more than a decade ago I knew that I’d found something special. I’ve sold other pad printing equipment and various types of assembly machinery, but I have never worked with something that was so elegantly designed. TOSH machinery combines speed, flexibility and power unlike any other pad printing equipment I’ve seen before or since. Every aspect is designed with purpose and function in mind.

Over the intervening years I’ve worked on thousands of applications with customers whose skill levels range from expert to non-existent. I’ve answered the question "Why should I buy your machine?" at least a thousand times.

The fact is that there are hundreds of reasons to trust your production to a TOSH machine. With this document I’ve tried to create an exhaustive list of those features that put us head and shoulders above our competitors. When you’ve had a chance to review them I hope that you will be able to step back and see that our equipment is more than the sum of its parts. It has been designed from the ground up without compromise. That is the true TOSH advantage.

Just the Facts

Each piece of TOSH equipment is conceived, designed and built as a modular building block. There are no uni-tasking machines in the product range. Individual components can be combined in various combinations to achieve a wide variety of tasks. All equipment has a clear upgrade path in terms of speed and flexibility. The rigor of this design philosophy results in elegant design solutions that satisfy a broad range of customer demands. There are plug in solutions for your application, we do not need to re-invent the process for you, nor do we need to force a marginal solution because our equipment doesn’t have the flexibility to do the job that needs to be done.

Mechanical Advantages

Cast Aluminum Alloy Body

TOSH designers prefer that every aspect of the machine serve its final purpose: printing. This includes the basic chassis of the machine.

One of the key aspects of accurate, high quality, high speed printing is rigidity. Torque, whip and vibration cause distortion. Torque, whip and vibration force the operator to slow the machine down. In essence, these factors require you to baby the printing process.

By employing a tough as nails aluminum alloy body TOSH starts off on the right foot. Typical pad printers use a machined interior skeleton and then cover everything with a bent metal box. Every gram of material that goes into a TOSH machine serves a purpose. What purpose does a sheet metal housing serve? Sheet metal is prone to feeling the effects of torque, whip and vibration. A heavy duty machined casting eliminates these problems.

All Electric Drive and Function

Every piece of TOSH equipment is all electric. No compressed air is necessary to run any of our print heads or conveying accessories. There is more information related to stepper motors and precision control below, but simply focusing on the use of electricity instead of compressed air is of significant value.

Start with the simplicity of a single plug. As long as you have electricity you can run TOSH equipment. There is no need to plumb in air. This makes the machine substantially more mobile so that as production demands change, you can move your machine to where it is most needed. For instance, the addition of a TOSH machine to a clean room environment is a snap.

Preventative maintenance on TOSH equipment is nearly eliminated. Without cylinders and their associated issues TOSH equipment requires very little care. There is no worry about filters, water or oil in the lines, seal failures, gummed up valve banks, etc.

TOSH machines are quiet. Compressed air is a substantial contributor to the overall noise pollution of your shop floor. Quiet electric drives keep the dB rating low.

TOSH machines are consistent in terms of speed and force. Once you’ve programmed a TOSH machine, the cycle remains the same until you change it. If you’ve ever set up a job on a pneumatic pad printer you’ll know that changing the speed of the machine often changes the distance and force of the machine. Cylinders take time to fill and settle. Variations in compressed air line pressure and volume will effect print cycle speed and print quality. With an electric drive you are guaranteed smooth consistent application of force at extreme production cadences.

It’s very unlikely you are going to run out of electricity in modern day America, running out of compressed air at the end of a drop line 100 feet away from your compressor is another matter all together.

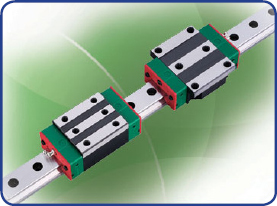

Linear Guideways

In order to take full advantage of the robust construction of our printer bodies, as well as the power and speed of our all electric stepper motors, TOSH machines only use the best linear bearings for motion control.

A linear guideway consists of a hardened steel rail and a saddle with recirculating bearings. Most of you know of these products by various brand names such as THK or Thompson. Bear with me as I go into a little more detail as to why we use them and why linear guideways provide superior control and performance.

Linear guideways can achieve higher precision linear motion when compared with a traditional slide or shaft. Compared with these older technologies the coefficient of friction for a linear guideway is 1/50th. Because of the way the saddle is captured and loaded on the rail, linear guideways can take loads in both the vertical and horizontal directions. This greatly enhances moving accuracy as well as stability when under load.

High Positional Accuracy

When a load is driven on a linear motion guideway, the frictional contact between the load and the bed is rolling contact rather than a sliding one. The coefficient of friction is 1/50th of that of a traditional contact and the difference between dynamic and static friction is very small. Therefore, there should be minimal slippage while the load is moving.

Long Life with High Motion Accuracy

With a traditional slide inadequate lubrication causes wear between the contact surfaces which become increasingly inaccurate. In contrast, rolling contact has little wear; therefore, machines can achieve a long life with a highly accurate motion.

High Speed Motion with Low Driving Force

Because there is little friction, only a small driving force is needed to move a load. This allows us to size motors based on the force needed for the print job, not for overcoming friction.

What all of this means in terms of a TOSH pad printer is that torque, vibration and whip are minimized or eliminated. This improves print quality and allows the machine to run at higher production cadences. The machine is going to go exactly where you program it to go at the speed you want it to travel. It can reverse direction on a dime and accelerate and decelerate without taxing the motor or increasing vibration.

It also means that your print tolerances typically run better than +/- 0.01MM per color. Accuracy over time does not degrade either as quickly as tradition methods of motion, or to such a degree.

Maintenance on a linear guideway consists of pumping clean oil through a standard nipple about once a year and cleaning the rails with solvent to remove dust and debris that have accumulated over that time.

Stepper Motor Driven:

All TOSH machinery is stepper motor driven.

TOSH was the first company in the industry to employ stepper motors on its standard equipment. The first all electric TOSH machine was introduced in 1984. This means that TOSH has a 25+ year track record of installing, programming and servicing all electric pad printing equipment. For other companies motor driven machinery is a risky change of direction, for TOSH it is an engineering tradition dating back to the inception of the company.

Properly programmed, stepper motors provide precise control over speed, stroke and force. Once a TOSH machine is programmed to go a certain distance, at a certain speed it will do this until you change the program. This is clearly untrue of pneumatic systems which are subject to variations in air volume and pressure. (A detailed description of our controls package is discussed in the Electronic Advantages section.)

Stepper motors are incredibly reliable and require no specific maintenance. In more than a decade of installing TOSH equipment in the USA, we have replaced a total of five motors. Two of these replacements were due directly to lightning strikes on the buildings in which the machines were housed. When compared with pneumatic components stepper motors are substantially more reliable. There are no wear components in stepper motors, no seals, no risk of contamination with dirty air.

Stepper motors are simple and inexpensive. Think of the process as a dial divided into 100 steps. The controller tells the stepper motor to go clockwise or counter clockwise a certain number of steps. It could be 1 or 10,000. The motor moves the described number of steps and stops until it receives further instructions from the controller. This is all done with electrical impulse. There are no valves to adjust and no mechanical stops to fiddle with. Every aspect of the machine becomes simplified because every single control is at the operator’s fingertips.

Stepper vs. Servo Motors

We frequently get the question of why we use stepper motors instead of servo motors. Since we’re on the cutting edge of pad printing, why aren’t we using what is touted as the latest and greatest technology? While we accept the fact that servo motors are a great technology for motion control in some applications, we do not feel they are the best approach for pad printing equipment for a number of reasons.

Stepper motors and servo motors are very similar. They are both electric motors with drive shafts that rotate at programmable RPM and produce a certain amount of torque. The main difference is in the open-loop controls of the stepper motor versus closed-loop controls of servo motor. On the face of it, the fact that servo-motors have an encoder constantly providing feedback to the controller about location seems like a good thing. However in terms of pad printing this provides no advantage.

The feedback loop of a servo motor serves to correct for positioning errors as the motion is occurring. For instance if we told the printer to stroke 50mm in print position and it encountered an issue the servo controller would continue to push the motor until one of three or four things happened. One, it reach the 50MM position because the obstacle was removed. Two, a programmed time out occurred. Three, the motor over currented and the servo controller told it to idle, or brought the machine home. Four, in theory, the motor could continue to beat its head against the wall until it burned out.

With a stepper, the motor runs through the programmed coordinates that are provided by the controller. If the motor encounters an obstacle that it cannot over come, say over compressing the pad on the part, it will slip. Our controller tells the pad to retreat to home position and then continue. No damage occurs to the motor or the electronics.

In a real life pad printing situation the only common blockage of movement that would cause a loss of steps or take advantage of the closed-loop feed back of a servo encoder is when the pad is being over compressed on the plate or on the part. It is precisely at these times that you want the machine to "slip", not continue on trying to push past the over compression point.

Why?

The machines are sized to produce a certain amount of force. For argument’s sake let’s say 250 kilos. The entire structure of the machine is built to work comfortably within that zone. Let’s say that by mistake the operator accidentally put in a pad that was 2x as hard as the one typically used for the job. In order to compress this pad the same distance it takes 400 kilos of force instead of 200 kilos. Would it be wise to continue pushing the motor and the structure of the machine? Of course not, and any well written program for a servo motor would make sure that it didn’t happen. So what then is the advantage of having the servo motor with an encoder when the stepper motor will respond in precisely the same way?

A common objection is that steppers could lose steps during the process of counting. However, in reality with a properly sized system, it is very unlikely that the motor will lose steps. With our systems, the controller keeps track of home position and makes adjustments if and when they are necessary. This is done with two simple proximity sensors, rather than an encoder.

Another common point is that servo motors can work at higher speeds. This is true and may be important in some processes, but not with pad printing. TOSH already manufactures the fastest pad printing machinery in the world. With most of our equipment and in comparison to most of our competitors the factor is at least 2:1. In many cases it is as high as 4:1. Our speeds bump up against the limit of the pad printing process itself, let alone practical handling of parts by an operator. The excellent "low speed" torque of a stepper motor makes it ideal for pad printing. Speed is relative. Do you need a 747? Or will a Ferrari do the trick when you’re competing against a golf cart?

Combine all the technical reasons above with the fact that stepper motors substantially less expensive and it becomes clear why steppers are the obvious motors of choice for TOSH pad printing machinery.

True U Shaped Motion

The motion of a traditional pad printer is driven by two cylinders. The horizontal cylinder moves the pad carriage and the cups front to back and the vertical cylinder moves the pads up and down. This motion has been described as "U" shaped. In fact, this is not the case because there is no curve in the motion. The cylinder slams down onto the plate, up to home position, then forward to print position and down onto the part. It would be more correct to call it a "box" shaped motion. This motion, by its shape, directs all the momentum of the machine into very jarring stop points and thus increases vibration. This effect is so well known that machines are set to slower speeds to allow the pads to settle before pick up and printing, otherwise the vibration of the stop points will transfer into the image and result in blurriness and distortion.

TOSH has solved the problem in a different way. Rather than slow the process down to work with the limitations of poor design, TOSH has developed a truly "U" shaped motion.

TOSH’s stepper motor drive moves a main cam. This is done either via a double belt/ chain drive, or via a direct drive gearbox depending on the machine model. This main cam moves the pads both vertically and horizontally simultaneously through the doctoring motion. This means that the momentum of the machine is mitigated and there is no stop point to create the vibration in the first place. The machine itself moves in a smooth, easy motion. A TOSH machine can run 30-50% faster than a competitive machine and appear to be running more slowly because there are not traumatic stops and starts. This not only improves print quality and total output, it also improves machine reliability. Think about your knees when you’re out for a run. While our competitors are running barefoot on concrete, TOSH is sliding along smoothly on an elliptical trainer.

Features

Suspended Cliché Support

Look closely at the brochure for your TOSH machine and compare it to our competitor’s. You may notice something that doesn’t seem so important at first. The knee on competitive equipment starts at the front of the cliché. TOSH cliché supports are suspended and open under the cliché. What does this mean for you?

It simply means more room: room for your part, room for your fixture, room for your conveyors. If you’re printing a small image in the middle of a big part, on competitive equipment you’d need a big machine to gain the reach necessary. On TOSH equipment because even our smallest machines are wide open under the cliché support, you can reach into the middle of parts that would be impossible otherwise.

Flexible Cliché Support/Cup Support

On TOSH equipment you have a blank slate to set up your ink cups and pads where you want them. A TOSH machine isn’t simply a 4 color 90MM machine on a fixed pitch. You can move your plates and cups around on the cliché platform where you need them and you can mix and match cup and cliché sizes as needed.

Eco/Utility Friendly

It’s a simple formula: All Electric = Green

We mean this not only in terms of the environment, but also your wallet.

Compressed air is one of the largest secret sources of waste. Its generation, use and storage is incredibly inefficient on every level. It starts with the fact that it requires the user to take a perfectly functional power source, electricity, and convert it into another form. If you’ve stood near a compressor at a factory, you know how much energy is wasted in this equation. That heat you’re feeling didn’t generate itself. It is pure unadulterated waste. From there you need to "condition" this new power with a chiller so that it doesn’t destroy your machinery down stream with moisture. A chiller is exactly what it sounds like, a giant air conditioner for your compressed air. How much does that cost to run day in and day out?

Once it leaves the tank, compressed air fills your factory lines and, well… leaks out of every single joint and connector. 30% of compressed air generated in a typical factory is lost due to leaks small and large. Think about that. After the inefficiency of converting electricity to compressed air, you’ll lose another 1/3 before it even gets to a machine!

Our smallest machine, the TOSH Micro 90 will save you approximately $500.00 per shift per year in operating costs. This number is purely related to the electrical usage. Maintenance of the compressor and chiller is not factored in. As machine sizes increase, savings do as well in proportion to the amount of force generated by the machine and the number of cycles per hour. We’ll be happy to work up an energy audit for you on any system we provide.

More Features

Proprietary Controls and Software

If the stepper motor is the heart of a TOSH machine the controller is obviously the brain.

TOSH uses proprietary controls and software to run all of its machinery and conveying accessories. This is truly out of necessity. TOSH was (and still is) building machinery unlike any of its competitors. Off the shelf programmable logic controllers are too expensive, cumbersome and slow for TOSH modular equipment. TOSH designs its controls from the ground up for the pad printing process.

Twenty five years of continuous development, field testing and improvements have led to the most advanced controls package in the pad printing world with a sustainable and stable upgrade path for every machine built.

Built in Upgrade Path

One of the key advantages of TOSH’s obsession with controls is that there is a viable upgrade path for every machine in the field within the limits of its size. In modern manufacturing, production requirements change constantly. Today a table top machine with a 2 position indexer might suit your needs exactly. In a month, you could need a high speed rotary table. Rather than having to go to a third party vendor for conveying accessories, TOSH already has a plan in place for you. Since TOSH builds all of its own conveying accessories it is only a question of a few hours of assembly to add a rotary table and reprogram the software. Every TOSH machine comes with built in controls for a range of conveyors and parts position devices.

Complete Cycle Control

Every TOSH machine allows for complete control of the cycle through the keyboard of the machine. This is unheard of on competitive equipment and is a function of TOSH’s stepper motor drive and proprietary software. Included on every machine are:

Independent Speed Control in Every Axis of Motion

There are 6 motions in every pad printing cycle. Doctoring forward, doctoring backward, pad down over plate, pad up over plate, pad down over part and pad up over part. If you’ve pad printed, you know how critical these speed are to a quality print. This being the case, why do many manufacturers ignore these controls, or put them out of reach of the operator? TOSH puts them at your finger tips.

Independent Delays/Timers in Every Axis of Motion

Why slow down the overall cycle, when all you need is a 1/10 second delay to allow the ink to tack off before printing? What if you want to pause on the part for ¼ second to allow the pad to conform to a difficult texture? With TOSH equipment you have the opportunity to program delays before ink pick up, on the cliché, before print and on the part. Once you’ve used these features to fine tune your process you will never be able to use a machine without them again. (Which, unfortunately for our competitors, is every other machine on the market today.)

Independent Stroke Adjustment in 1MM Increments over the Cliché and Part

Have you been using limit switches and knobs to adjust your strokes? Does your machine have no adjustment at all? Why not just tell it where you want it to go? With a TOSH machine, if you need 1mm more or less compression, you push a button and you’re there. Exactly what you need, when you need it.

Training Mode

When setting up your machine for a new application, TOSH software gives you the flexibility to walk the machine through the cycle. By holding a button you can slowly jog the machine into position, hit enter, and the machine learns the stroke. Training mode allows you to quickly set up a new program (which can be stored to memory) in seconds.

Stepping Mode

All motions of the machine can be run independently when the machine is put into stepping mode. Isolate doctoring, pad stroke, or indexing so you can see exactly what your machine is doing. This can be run at full speed, or in incremental steps.

7 Languages

All TOSH machines are meant to travel. They can be programmed in English, Italian, Spanish, German, Portuguese, French and Swedish. You can toggle between these languages as needed.

Multi-Program Memory

Programs can be stored in the memory of the machine for immediate recall.

Easy to Automate

TOSH machines are easy to automate. If you are using TOSH conveyors, you can mount the accessory and add the necessary driver card and call up the program that is pre-loaded into the controls package. If you wish to integrate TOSH equipment with your line, there are all the necessary inputs and outputs present, built in for your convenience.

Counters

TOSH machines have a number of useful counter features. There is an overall life cycle counter for the machine itself. There is also a batch counter to help you keep track of each job. The machine will also provide you with a live "cycles per hour" counter so you can see how much production you should expect from a certain set up over the course of a shift.

Conclusion

I’ve heard the phrase "all pad printers are the same" week in and week out for more than a decade. One thing I can promise you is that this is not true. With all of these features TOSH makes many impossible print jobs possible, marginal print jobs standard and easy jobs serious money makers. I believe it is critical when you sit down to make a final decision on your pad printing equipment purchase that you take into account not just the "bottom line" price of the equipment but the real bottom line production cost for your parts. If you’re committed to manufacturing in the USA, you know that a zealous commitment to efficiency, speed and precision are your only chance at fending off the competition. It is a fact that you have to pay your workers ten times the rate of any overseas manufacturer. It is my suggestion that you level the playing field by providing them with the best tools for the job. Increase your real output, decrease your set up times and watch your margins improve. Isn’t this what real productivity is all about?